Munyika yezvikamu zvemotokari, kunyatsorongeka uye mhando ndizvo zvinonyanya kukosha. Kubva pakugadzirwa kwekutanga kusvika pakugadzirwa kwekupedzisira, chikamu chimwe nechimwe chinoitwa nenzira yakangwarira kuti chive nechokwadi chekuti chinoshanda zvakanaka. Chimwe chezvinhu zvakakosha iimba yegiya realuminium. Mublog rino, tichaongorora nyika yakaoma yekugadzira mold, kukosha kwema prototypes, uye mitemo yakasimba yemhando inoita kuti dzimba dzegiya realuminium dzibudirire muindasitiri yemotokari.

Unyanzvi hwekugadzira Mould

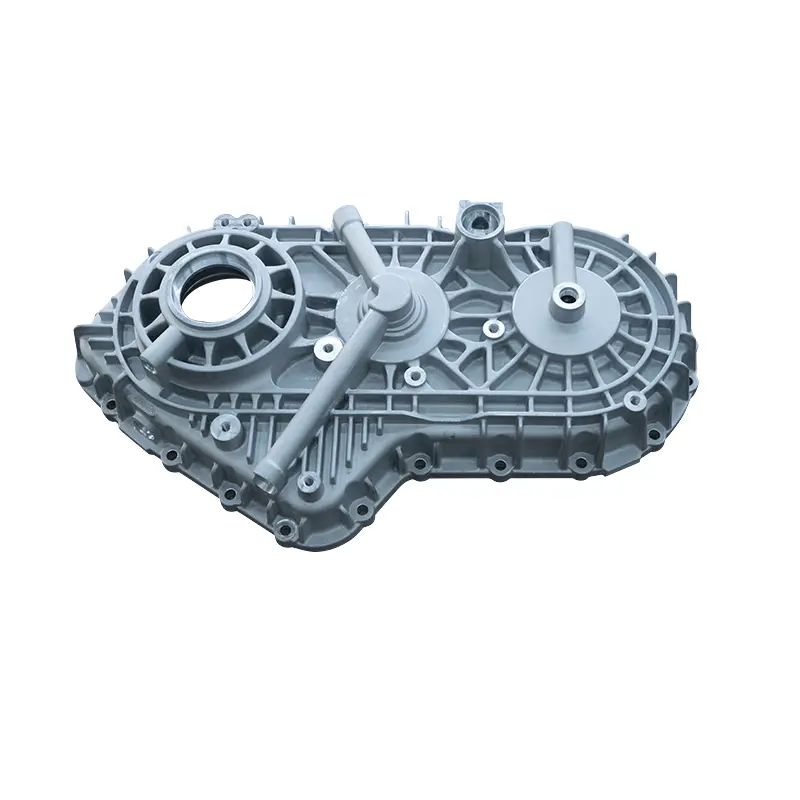

Kugadzira magiya emhando yemold kunoita basa guru mukugadzira magiya ealuminium. Nekubatsira kwemidziyo yazvino, magiya anogadzirwa nemazvo kusvika padanho repamusoro. Kunyatsoita izvi kunobvumira kugadzirwa kwemagiya asina matambudziko, zvichiita kuti mashandiro ashande zvakanaka mukati memota. Maitiro aya anosanganisira kushandisa matekiniki epamusoro senge computer numerical control (CNC) machining kuti awane maumbirwo nehukuru hwaunoda. Nyanzvi dzemagiya dzine ruzivo rwakadzama dzinoshandisa hunyanzvi hwadzo kugadzira magiya anozogadzira magiya emhando yemold. Kupera kwepasi kusina kuchena, magadzirirwo akaomarara, uye zviyero chaizvo zvese zvinowanikwa kuburikidza nehunyanzvi hwekugadzira magiya.

Kubatsira kwemuenzaniso

Vatengi vanowanzoda prototype yeimba yegiya realuminium kuti ive nechokwadi chekuti inosangana nezvavanotarisira. Danho iri rinobatsira kuona chero zvikanganiso zvekugadzira, kugadzirisa zvinodiwa, uye kugadzirisa chigadzirwa kuti chienderane nezvinodiwa nemutengi. Prototypes dzinogonesawo mainjiniya kuongorora kuti imba yacho inoenderana sei nehurongwa hwemotokari uye kuongorora kugara kwayo kwenguva refu. Nekugadzira prototype, vagadziri vanogona kugadzirisa dhizaini yacho uye kugadzirisa chero chinhu chinodiwa vasati vagadzira zvizere. Izvi zvinovimbisa kushanda zvakanaka kwemutengo uye kugutsikana kwevatengi, ukuwo zvichideredzawo njodzi yekukanganisa kana kudzoka.

Kuzvipira Kuhunhu Hwakanaka

Hunhu ndiyo musimboti wekugadzirwa kwedzimba dzemagiya ealuminium. Kubva pakusarudza zvinhu kusvika pakugadzirwa kwekupedzisira, vagadziri vanotevedzera matanho akaomarara ekudzora hunhu. Danho rega rega rinotariswa uye rinoedzwa kuona kuti chigadzirwa chapedzwa chinosangana kana kudarika mitemo yeindasitiri. Midziyo yepamusoro yekuongorora hunhu inoshandiswa kuona chero kutsauka kubva pane zvakatemwa, ichivimbisa kuti imba yega yega yegiya haina chakaipa pakushanda uye chitarisiko. Vagadziri vanoitawo bvunzo dzakasimba dzekushanda, vachitevedzera mamiriro chaiwo asati asvika chero chigadzirwa kumusika. Kuzvipira uku kune hunhu kunovimbisa kuvimbika uye kugara kwenguva refu kweimba yegiya realuminium, zvichigutsa vagadziri nevashandisi vese.

Indasitiri yemotokari inovimba nekunyatsorongeka, kushanda zvakanaka, uye kugona. Kugadzirwa kwemidziyo yegiya realuminium kunoratidza kuzvipira uku kusvika pakukwana. Kuburikidza nekugadzira mold zvine hungwaru, kugadzira ma prototypes, uye kuzvipira kusingazununguki kune mhando, vagadziri vanovimbisa kuti imba yega yega yegiya box inomira zvinoenderana nezvinodiwa nenyika yemotokari. Nekufambira mberi muhunyanzvi hwekugadzira uye mwero weindasitiri unoramba uchichinja,dzimba dzegiya rearuminiyamu Vanoramba vari pamberi mukuvandudzwa kwemotokari, vachipa kugara kwenguva refu, kuvimbika, uye kushanda zvakanaka.

Nguva yekutumira: Nyamavhuvhu-03-2023