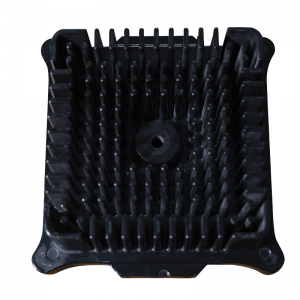

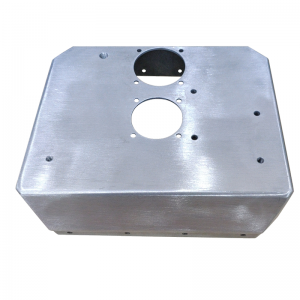

Heatsink yakagadzirwa neDie-cast yeRadiator

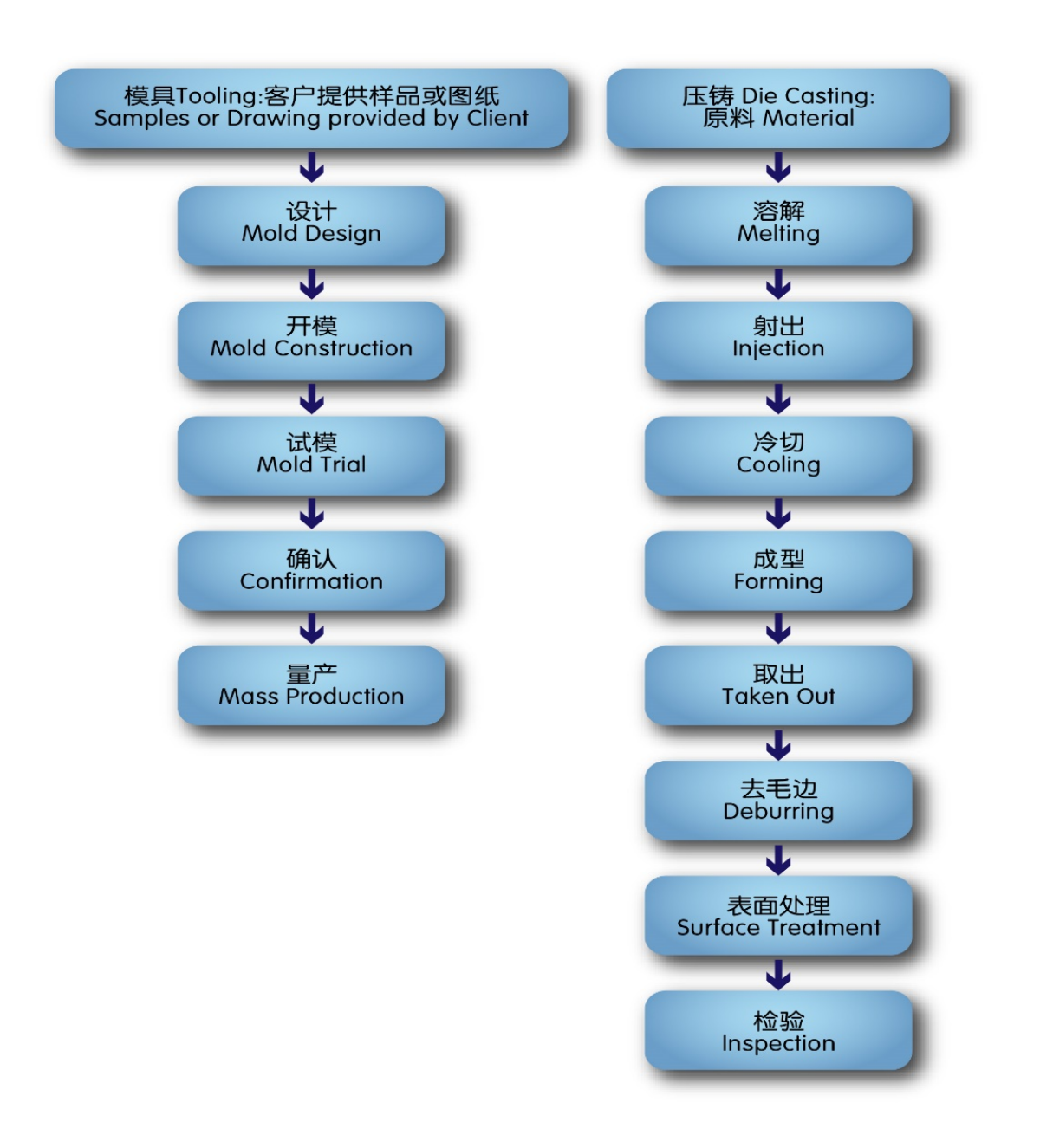

Maitiro ekudziya sink

Dhizaini yezvishandiso

Kukanda kufa kwekumanikidzwa kwakanyanya

Kucheka

Kubvisa mabhatiri

Kuputika kwejecha

Kupukuta pamusoro

Kuputira Upfu

Kubata & kugadzira CNC

Chinopinza chemupendero

Kurapa Kwepamusoro

1. Kuoresa kwemakemikari

2. Kupenda

3. Kushandiswa kweElectrophoresis

4. Kuomesa

5. Kuputira upfu

Masinki ekupisa akakandwa

Masinki ekupisa eDie cast akakodzera kana uchida sinki yekupisa yealuminium yakagadzirwa neanuminiyamu. Anogadzirwa nekumanikidza aruminiyamu yemvura pasi pekumanikidzwa kwakanyanya kuita maforoma esimbi. Sinki yekupisa yeDie casting inozivikanwa mumusika nekuti yakagadzirwa nearuminiyamu alloy. Ichi ndicho chinhu chinodiwa pasinki yekupisa yeDie casting. Maitiro aya ekugadzira die casting akakodzera kusangana nezvinodiwa zvepurojekiti uye akagadzirwa nekukurumidza.

Nguva yekukurumidza yekutungamira mazuva 35-40 chete

Kushanda Kwakanyanya pakupera kweanodized pamusoro

Zviyero zvakasimba zvakasimba zvinodzorwa mukati me +/- 0.05mm

Mainjiniya anobatsira kupedzisa kubva pakugadzira kusvika pakugadzira

Mabhenefiti eDie Cast Heat Sinks

Kana tichienzanisa nedzimwe nzira dzekugadzira, die casting inopa mabhenefiti anotevera:

1. Gadzira maumbirwo akaomarara e3D asingagoneke pakuburitsa kana kugadzira

aluminium heat sink, furemu, imba, nzvimbo yakavharirwa uye zvinhu zvinosunga zvinogona kusanganiswa muchikamu chimwe chete chekukanda

2.Makomba anogona kuchekwa mu die casting

3. High kugadzirwa mwero uye yakaderera mutengo

4. Kushivirira kwakasimba

5. Yakagadzikana pachiyero

6. Kugadzira michina kwechipiri hakudiwi

Isa nzvimbo dzakati sandara (dzakanakira kubatana pakati pechitofu nechinhu chinobva mvura)

Kudzivirira ngura kubva pakanaka kusvika pakakwirira

Kuyerera kwemaitiro eKingrun

Kana tichienzanisa nedzimwe nzira dzekugadzira, die casting inopa mabhenefiti anotevera:

1. Gadzira maumbirwo akaomarara e3D asingagoneke pakuburitsa kana kugadzira

Sinki yekupisa, furemu, imba, nzvimbo yakavharirwa uye zvinhu zvekusimbisa zvinogona kusanganiswa muchikamu chimwe chete chekukanda

2.Makomba anogona kuchekwa mu die casting

3. High kugadzirwa mwero uye yakaderera mutengo

4. Kushivirira kwakasimba

5. Yakagadzikana pachiyero

6. Kugadzira michina kwechipiri hakudiwi

Isa nzvimbo dzakati sandara (dzakanakira kubatana pakati pechitofu nechinhu chinobva mvura)

Kudzivirira ngura kubva pakanaka kusvika pakakwirira

Kudzivirira kwakanaka kweEMI neRFI